EPDM cast rubber stands out as a frequently preferred material in industrial applications. The term EPDM is an acronym for ethylene propylene diene monomer rubber, known for its flexibility, durability, and resistance to weather conditions. Has Rubber continues to lead the industry in the production of EPDM cast rubber. This type of rubber is widely used across various sectors, from waterproofing to automotive applications.

What is EPDM Cast Rubber?

EPDM cast rubber is a specialized type of rubber obtained through various chemical processes. Its elastomeric structure gives EPDM rubber superior flexibility and durability. EPDM material is highly resistant to UV rays, ozone, and extreme temperatures, making it an ideal choice for outdoor applications. Has Rubber has established itself as a reliable producer of EPDM cast rubber by consistently delivering high-quality products.

EPDM Cast Rubber Production Process

The production of EPDM cast rubber involves several stages, ensuring the material’s durability and flexibility. First, ethylene, propylene, and diene monomers are subjected to a polymerization process under high pressure and temperature. This chemical process forms the rubber’s fundamental structure, providing attributes such as elasticity and resistance. Has Rubber, with its modern production facilities and R&D processes, offers top-quality products. Every stage of the production process adheres to stringent quality control procedures, employing sustainable and eco-friendly manufacturing methods.

Applications of EPDM Cast Rubber

EPDM cast rubber has a broad range of applications and can be adapted for use in various industries. In the construction sector, EPDM material’s unique properties are utilized for waterproofing purposes. It is commonly used in roofs and other outdoor areas to protect against water damage. Additionally, in the automotive sector, EPDM rubber is frequently employed in components like door seals and window gaskets. Its cost-effective and durable nature are among the factors that make Has Rubber’s EPDM cast rubber highly popular.

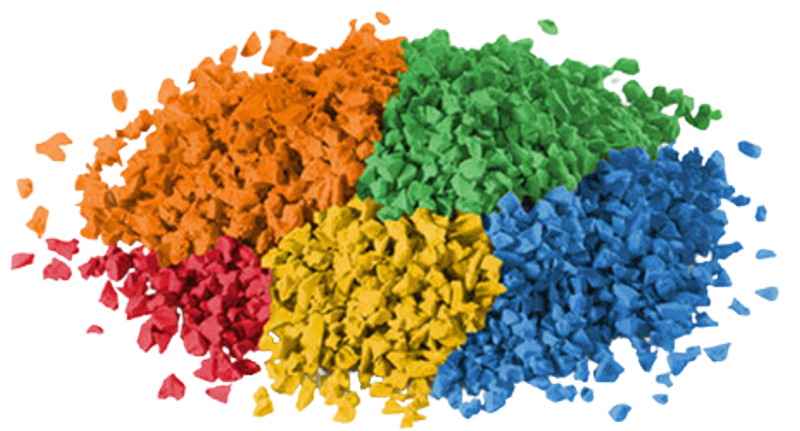

Comparison of EPDM Cast Rubber Types

Different types of EPDM cast rubber can be customized based on application and usage areas. For instance, some EPDM types are known for their high-temperature resistance, while others offer greater flexibility. Has Rubber is dedicated to providing the most suitable EPDM blend to meet customer needs. The company works on various formulations and thicknesses, producing tailored solutions for specific projects.

Challenges and Solutions Related to EPDM Cast Rubber

While EPDM cast rubber boasts numerous advantages, some challenges can arise. These include deformation caused by prolonged exposure to certain chemicals or extremely high temperatures. However, specialized companies like Has Rubber address these issues through the use of various additives and custom formulations, offering long-lasting EPDM cast rubber solutions. With proper guidance on the maintenance and care of EPDM materials, users can maximize the efficiency of this versatile material.

EPDM Cast Rubber: The Preferred Choice for Multiple Industries

EPDM cast rubber represents durability and reliability for many industries. Has Rubber, with its extensive product range and customer-focused service approach, has proven its leadership in the EPDM cast rubber sector. With its flexibility and versatility, this material has established itself as an indispensable solution for industrial activities of all kinds.