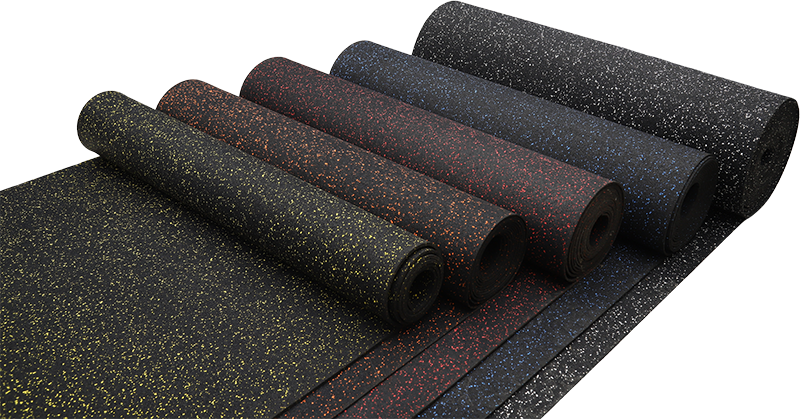

EPDM Roll Rubber, with its flexibility, durability, and versatility, has become an essential part of the industry. Has Rubber stands out in the sector with this high-tech product. EPDM, a type of synthetic rubber made from the combination of ethylene, propylene, and diene monomers, and its roll form maximizes the performance of the material.

What is EPDM Roll Rubber?

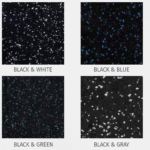

Properties of EPDM EPDM is known for its resistance to various environmental conditions. It offers excellent resistance to ozone, ultraviolet rays, hot air, and chemical attacks, making it a durable material used in a wide range of applications. This allows EPDM to be utilized in outdoor applications such as railway tracks, roofs, and various industrial sectors. Moreover, its flexible structure makes it easy to apply on different surfaces. Has Rubber provides reliable solutions to various sectors with its high-quality EPDM roll rubber production.

Roll Rubber and Its Applications

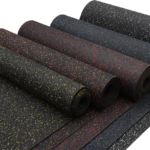

Roll rubber is a commonly used material in the industry. It is often preferred for large surface areas due to its quick and effective application. It is used in industrial flooring, sports fields, roofing, automobile tires, and many other fields. The unique properties of EPDM provide several advantages when used in roll rubber form. Has Rubber processes this type of rubber with expertise to deliver superior quality and durability to its customers.

Advantages of EPDM Roll Rubber

Durability and Longevity Thanks to its EPDM content, roll rubber provides excellent durability. This material is resistant to wear and is known for its long-lasting performance. In outdoor applications, where materials can quickly deteriorate due to sunlight and other environmental factors, EPDM provides a significant advantage. Has Rubber offers both durability and longevity to ensure maximum customer satisfaction.

Flexibility and Easy Application EPDM roll rubber, with its flexible structure, can quickly and easily adapt to various surface shapes. This feature speeds up installation processes and reduces costs. The lightness of the material minimizes labor requirements during transportation and application. Has Rubber emphasizes the advantages of this material in projects requiring special applications, enhancing efficiency in the supply chain.

Problems and Solutions with EPDM Roll Rubber

Common Issues Like any product, EPDM roll rubber can face some challenges. The most common problems include adhesion issues, edge curling, and discoloration over time. These issues can arise from improper application techniques or inadequate surface preparation. Has Rubber develops innovative solutions to eliminate these problems.

Solution Suggestions Surface preparation is crucial when dealing with such issues. Cleaning the surfaces thoroughly and applying the material with a trowel or suitable tools prevents adhesion problems. To avoid edge curling, proper stretching of the roll rubber is essential. Discoloration is minimized with the use of high-quality EPDM; therefore, Has Rubber guarantees the quality of its products by using only the best materials.

Expert Opinions and Consultancy Services

Has Rubber offers not only products but also expert opinions and consultancy services to its customers. These services proactively address potential issues that may arise during the application process and provide solutions. Especially in large projects, expert team guidance helps avoid potential mistakes, reducing project costs, saving time, and increasing customer satisfaction.

Conclusion

EPDM roll rubber has become an indispensable material in many industries. Has Rubber leads the sector with the quality and durability of its products. With its flexible structure, easy application on different surfaces, and resistance, it is one of the best options to meet project requirements. With its quality and customer satisfaction-oriented service approach, Has Rubber continues to stand out as a reliable business partner.