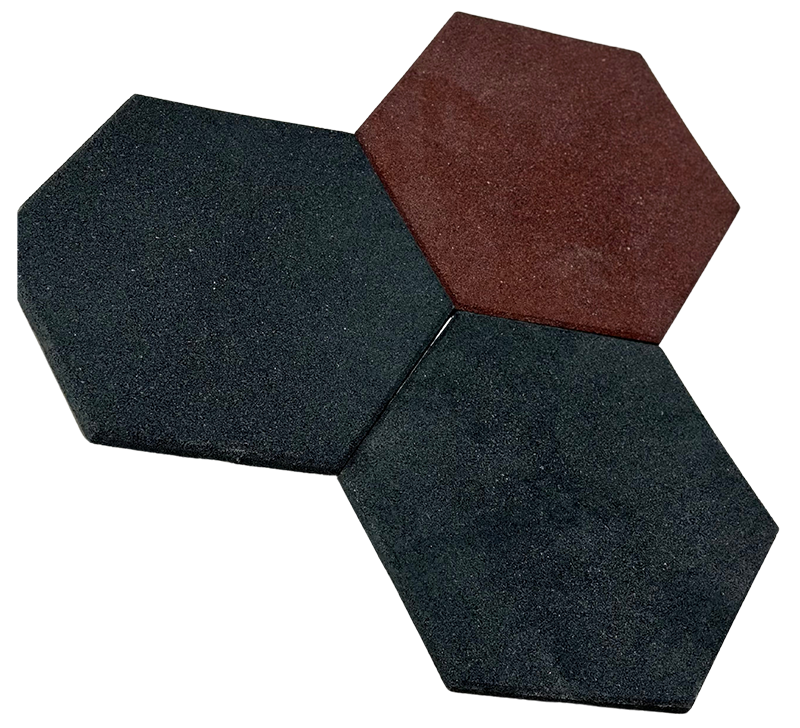

SBR Hexagonal Rubber is a material widely used in the industrial and construction sectors today, offering various advantages. Produced by Has Rubber, this product has become an indispensable part of many projects due to its flexibility and durability. Has Rubber, which provides innovative solutions in the rubber sector, aims to meet its customers’ needs and expectations in the best way possible.

What is SBR Rubber?

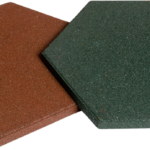

SBR rubber, short for Styrene-Butadiene Rubber, is often used as an alternative to natural rubber. This type of rubber has a wide range of applications due to its low cost and good performance. It has enhanced chemical resistance and performs well on abrasive surfaces. An important advantage is its resistance to weather conditions, which makes it a preferred choice for outdoor applications.

Has Rubber is known for its high-quality SBR rubber products, each designed with the most suitable features for their intended use. The rubber is especially dense and durable, even under excessive use. Additionally, it provides excellent sound insulation, making it a popular choice for spaces such as gyms, schools, and playgrounds. Has Rubber offers a wide range of products to meet various needs.

Why Use SBR Hexagonal Rubber?

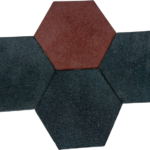

SBR hexagonal rubber is ideal for various applications. This type of rubber is notable for its structure, which adheres easily to surfaces and enhances safety. Has Rubber ensures better balance and stability with this special product. The hexagonal shape offers many benefits for application areas, as it adheres better to the surface, minimizes the risk of slipping, and ensures even pressure distribution. These features make it suitable for both commercial and industrial use.

Moreover, SBR hexagonal rubber is an eco-friendly material. It is generally made from recyclable materials, minimizing its impact on the environment. Due to its high chemical resistance, it is also easy to clean and maintains its form even with long-term use. With features like sound insulation and shock absorption, it is also ideal for indoor applications. Has Rubber provides these advantages to its customers, helping them achieve maximum efficiency in their projects.

SBR Hexagonal Rubber Production and Quality Control Processes

Has Rubber follows high-quality standards throughout the production process of SBR hexagonal rubber. Every step is carefully controlled, and the products undergo necessary tests to ensure optimal performance. The production process involves the correct mix of materials, shaping, and passing through various quality control checks. The goal of these processes is to increase the durability of the products and maximize customer satisfaction.

Quality control is critical for Has Rubber. Each SBR hexagonal rubber product undergoes various durability, flexibility, and environmental impact tests before leaving the factory. These tests ensure the products perform at their best in real-world applications. Has Rubber continuously follows technological innovations and best practices to enhance the quality and reliability of its products.

Uses of SBR Hexagonal Rubber

SBR hexagonal rubber has a wide range of applications. The advantages offered by SBR material make it a preferred solution in various sectors. This product, produced by Has Rubber, is commonly used in places such as gyms, children’s play areas, factories, and warehouses. Its flexible structure, durability against impacts, and sound insulation make these areas safe and comfortable to use.

In gyms, SBR hexagonal rubber is preferred as a flooring material. It reduces the risk of injury from falls while minimizing the impact of equipment on the floor. In children’s play areas, it creates a durable and safe surface for children to play on. In factories and warehouses, it provides a long-lasting solution by preventing wear caused by heavy loads and high traffic.

Considerations for SBR Hexagonal Rubber Applications

There are several factors to consider when applying SBR hexagonal rubber. Proper installation and mounting ensure the long lifespan and best performance of the material. Has Rubber also provides support to its customers in this regard, offering guidance during the application process if needed. Additionally, providing information on the correct cleaning and maintenance methods ensures that the products deliver maximum benefits.

It is essential that the surface where this rubber will be applied is clean and smooth. For reliable installation, the surface must be leveled and kept dry. Before installing SBR hexagonal rubber, checking that the surface does not contain any moisture is critical to enhance its adhesion and durability.

Has Rubber adopts an approach that never compromises on quality or service to maximize the performance and customer satisfaction of its products. Every SBR hexagonal rubber product is carefully produced and tested to provide the best user experience. The company offers a broad product range, capable of providing tailored solutions for different projects. Every piece made from SBR material is durable and reliable, thanks to customer-focused engineering and quality craftsmanship.